PartStrength

Application for the calculation of strength properties in a cross section of a machine part or construction element

PartStrength calculates the static and dynamic strength in a cross section according

the method developed in the text book Maschinenelemente Band 1 Niemann-Winter-Höhn 4. Edition 2005. This method involves

the determination of a lot of influence factors making the calculation work quite extensive. This application is intended to automate

the labourious calculation work.

User Interface

PartStrength is an application running under Microsoft Windows operating system.

The user can select the language for the user interface and output out of:

Identification of a Calculation Project

At the start of a new calculation project a dialog box is being opened for input of some data for the identification of the calculation

project. This dialog box contains edit controls for input of: order, project, subproject, item, part ID , calculated by, organization,

and date of calculation. A text box is also provided to hold a short note about the calculation project.

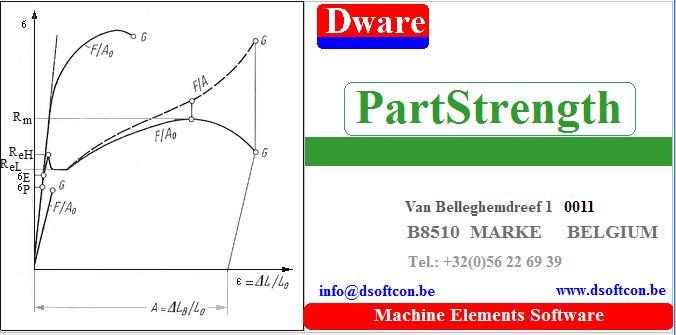

About the calculation method

The strength properties in the part are to be derived from material properties Rm

and Re of a standard test specimen with diameter d = 7.5 mm for a given material

by determination of a number of influence factors.

Material static strength properties in part cross section

- Determination of ultimate and yield strength in part by calculation of the technologic size and anisotropic influence factors

- Determination of shear strength and shear yield strength from the ultimate and yield strength in part

- Correct compressive strength and yield for cast iron materials

- Correct for the influence of higher temperatures > 100 °C

- Influence of stress concentration by determination of form factors

- Influence of plastic support and plastic notcheffect

- Influence of non linearity for lamellar cast iron GJL

- Determination of tensile, bending, shear and torsion strength and corresponding yield in part

- Calculation of safety factors for a given static load

- Calculation of safety factors for comparison stress with mixed failure criterion

Material dynamic strength properties in part cross section

- Determination of alternating tensile/compressive and shear strength for test specimen size using ratio's

- Determination of alternating tensile/compressive and shear strength in part by calculation of the technologic size and anisotropic influence factors

- Correct for the influence of higher temperatures > 100 °C

- Influence of stress concentration by determination of form α-factors

- Influence of plastic support by part form, geometric size and load case, determination of support factors

- Determination of alternating tensile, bending and torsional strength for unnotched part

- Influence of stress concentration by determination of elastic notch effect β-factors

- Influence of surface roughness in notch radius

- Influence of skin support by hardened layer or shot-peening

- Determination of alternating tensile, bending, shear and torsion strength in part

- Calculation of mean stress sensitivity coefficient

- Calculation of allowed bending and torsional stress amplitudes in part for given mean stress

- Calculation of safety factors for a given mean and dynamic stress amplitudes

- Calculation of safety factors for comparison stress with mixed failure criterion

Above summary suggest that there is a lot of calculation work to perform. See further for calculation results.

See next page for selection of material and input part size.