Cylindrical Compression Springs

Design of a Compression Spring

The objective is to determine the spring wire diameter and the coil dimensions for a given spring force and stroke.

The calculation is done according the standard DIN EN 13906-1. A wizard sheet is used to

guide the user through the calculation sequence.

Design Specifications

On opening of the wizard sheet, a wizard page with a list of spring wire grades is beeing displayed. A spring wire grade file

is supplied with the application. The file contains wire grades according the standards EN 10270-1, 2 and 3, EN 10089,

Copper-tin alloys EN12166. The user can update the spring wire grades file with data of the wires he will use.

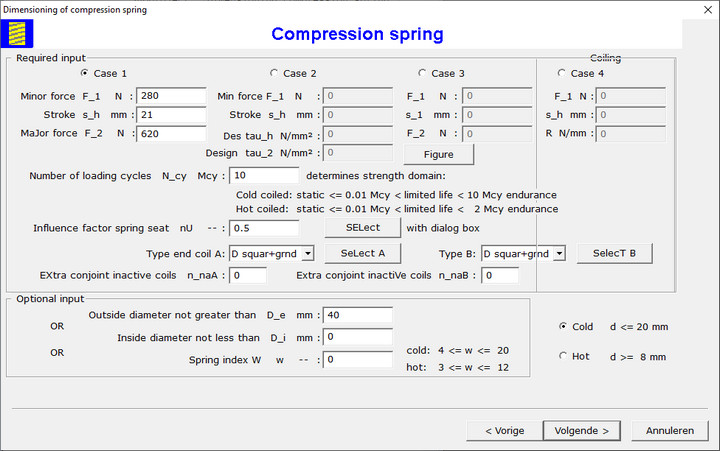

Input design specifications with following wizard page:

In figure above you can see the 4 cases for input of the spring load. Input of number of loading cycles Ncy, the influence factor

of spring seat ν and selection of end coils from list in combo box and eventual additional inactive adjacent coils at spring ends

A and B. Optional input as upper limit for coil outside diameter De and/or spring index w.

The application calculates the required wire diameter d. The user decides about the nominal wire diameter he's gonna to use.

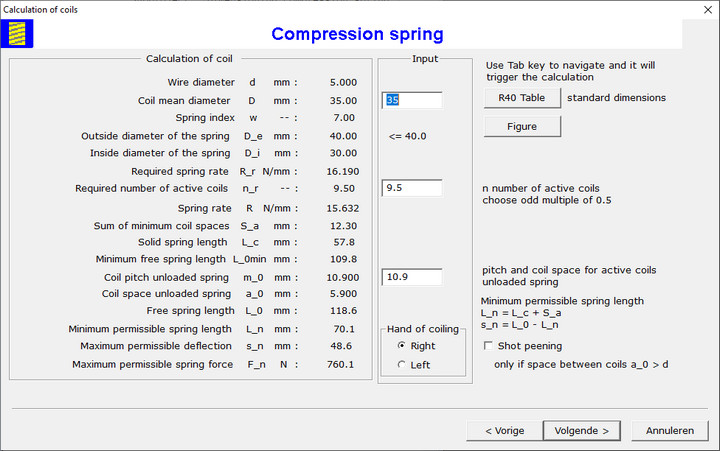

Then the following wizard page is beeing displayed with the geometry calculation results:

The user has to input his choice for the coil mean diamter D, the number of active coils n and the free state pitch

m0. The user has to select the hand of the coiling with a radio button and to check mark if the spring will be shot peened.

The calculation involves geometry, spring rate and strength. The calculation results are displayed in the next wizard page. Go to the next web

page for the design results and the spring diagram.