Gear ISO Accuracy Grade Qg

Input Gear ISO Accuracy grade Qg with a dialog box.

Gear Measurement

Input minimum normal backlash and backlash tolerance. The application determines:

|

Mean upper normal circular tooth thickness |

smn |

|

Mean upper transverse circular tooth thickness |

smt |

|

Mean chordal addendum |

hamc |

|

Mean upper chordal thooth thickness |

smnce |

|

Mean lower chordal tooth thickness |

smnci |

|

Mean tooth thickness tolerance |

Ts |

|

Whole depth |

ht |

Calculated data for measurements can be printed in a measurement sheet.

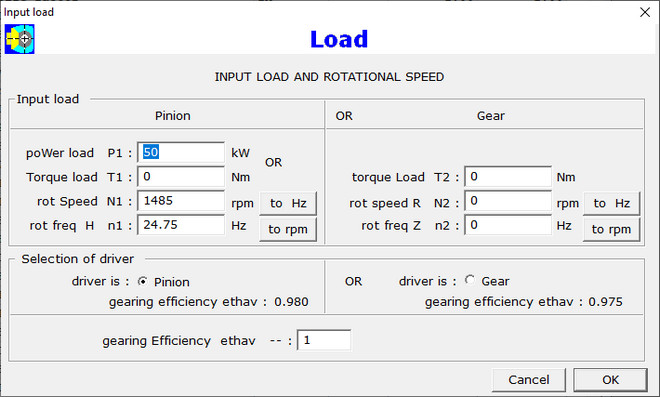

Gear Load

Input of gear load with one of the following combinations:

| |

Power on pinion |

P1 |

kW |

and |

rotational frequency of pinion |

n1 |

Hz |

| |

Torque on pinion |

T1 |

Nm |

and |

rotational frequency of pinion |

n1 |

Hz |

| |

Torque on gear |

T2 |

Nm |

and |

rotational frequency of gear |

n2 |

Hz |

Input with dialog:

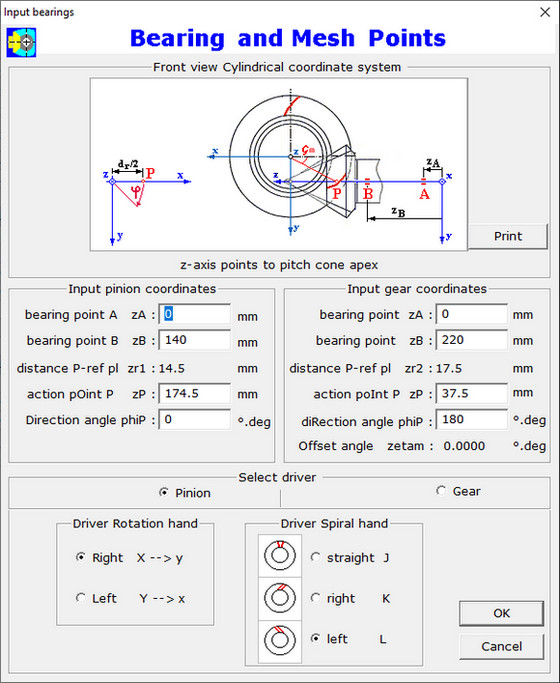

Bevel Gear Forces

Input of location of bearing points and of mean mesh point P in cylindrical coordinates as in following dialog box:

Calculation of transverse tangential force Ft, the radial force Fr and the axial force

Fa in mesh point and the reaction forces in the bearings. Axial force is minimal if the outer side of spiral of driver

points toward the rotation direction. If this is not the case, the application will warn that the spiral hand is not an optimal choice for

the given rotation direction.

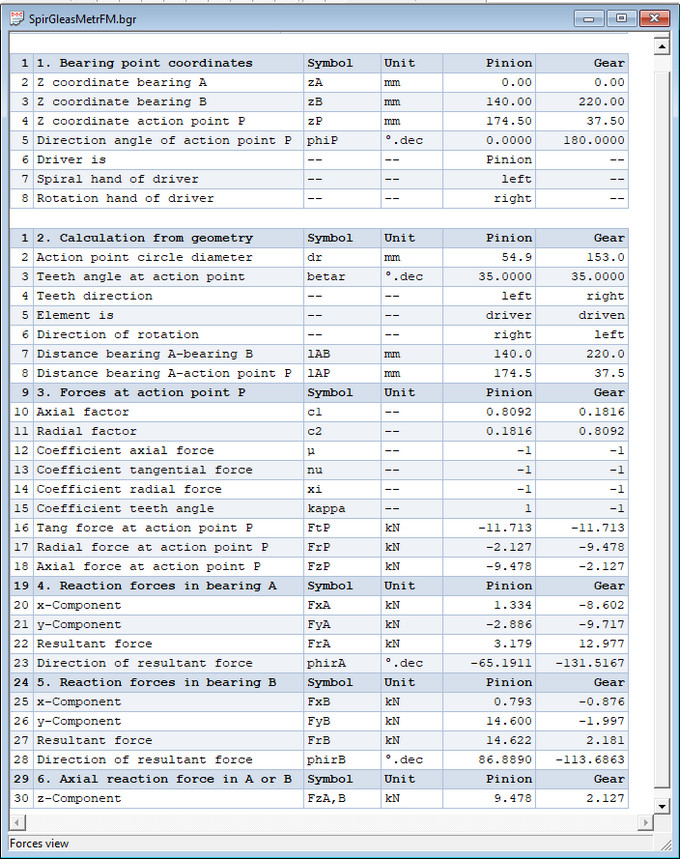

Calculation output in a window view in table form as shown in next figure:

With a mouse click on a menu item, the forces calculation report can be exported in a .txt - or a .html-file.

Click on Forces Calculation Report to open it in a blank page.

Go to the next page for the load carrying capacity.

|